|

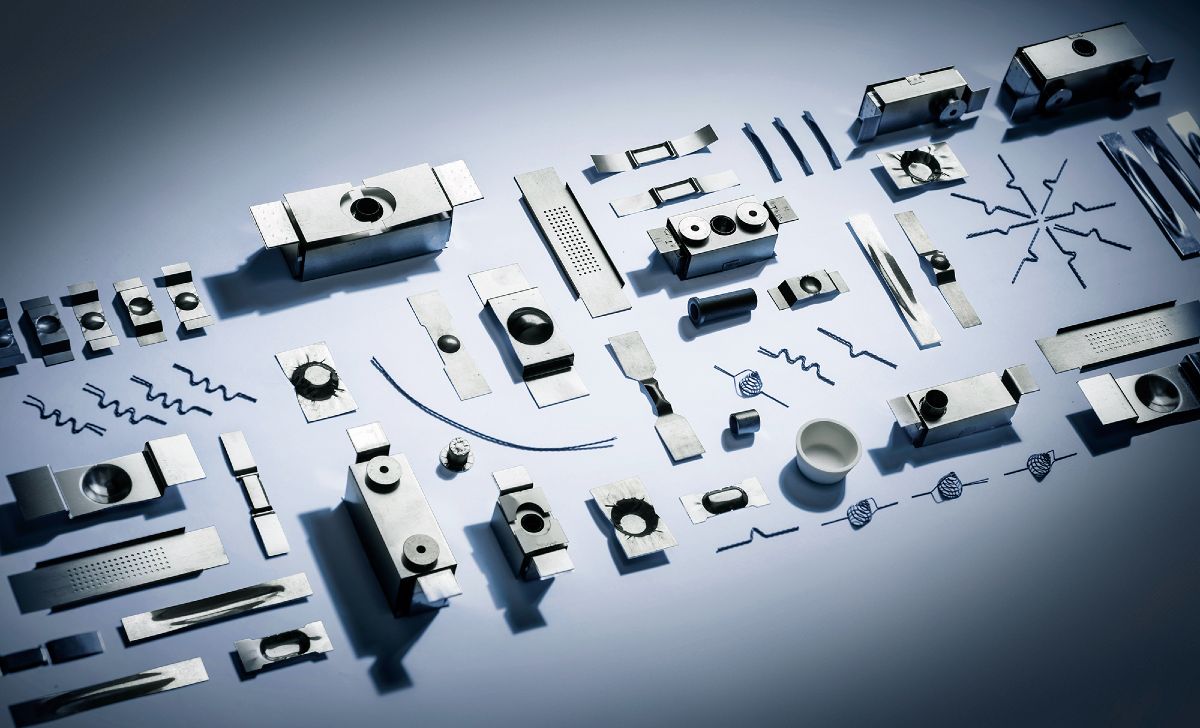

The most commonly used refractory materials are tungsten, molybdenum and tantalum. There are a number of evaporation source designs - multi-strand filaments, wire baskets, boats and crucibles. An electric power source with low voltage tappings and high currents will be needed. The boat evaporation sources are usually more demanding in their power requirements. Multi-strand (often three strand) tungsten filaments are typically used to evaporate metals such as aluminium or platinum. Tungsten wire baskets can be employed to evaporate chips or pellets of metals or dielectrics which either sublime or do not wet the basket when melting. They can also hold and heat crucibles containing the evaporant. |

Boat sources are also fabricated from tungsten, molybdenum and tantalum. Most elements and compounds can be evaporated from the standard boat sources, but where the material "wets" the complete boat (such as nickel) an aluminium oxide coated source may be considered. For highly dense uniform chromium films, chromium plated tungsten rods are available and baffle sources for materials such as silicon monoxide and zinc sulphide.

Filaments

Tungsten metalizing filaments are the industry standard for thin film depositions for a wide variety of materials. Testbourne offers an extensive selection of tungsten filaments to fit most applications as well as custom fabrication to meet your specific process needs.

Basket and Heaters

Tungsten Evaporation Baskets offer an effective method of reaching high temperatures with low current. The benefits of using tungsten baskets as an evaporation source for your deposition process include low cost, ease of use, multi-directional coatings and low power requirements.

Crucibles

The crucibles shown in this section are designed to fit into our baskets heaters and shielded crucible heaters. Custom sizes are available upon request.

Boat Sources

Evaporation Boats are capable of depositing a wide variety materials. Testbourne offers an extensive selection of standard tungsten boats, tantalum boats and molybdenum boats as well as custom fabrication to meet your specific evaporation source needs.

Alumina Coated Sources

Alumina coated evaporation sources have been developed to replace alumina crucibles for some specific applications.

Box Sources

The “Baffled Box” Silicon Monoxide Source, SiO source, has proven to be an extremely successful method of depositing Silicon Monoxide. Source material is positioned in the boat within separate cavities, when heated it follows an indirect path through a series of baffles and then out of the exhaust chimney.

Micro-Electronic Sources

Our Micro-Electronic sources represent a full line of smaller size sources that are similar to the standard size sources. The overall length on these sources is slightly less than 50.8mm (2 inches) in most cases. The smaller sources are ideal for lower power systems or processes that require small amounts of evaporants.

Chrome Plated Tungsten Rods

Testbourne offers an effective, user friendly way to evaporate chromium. The chrome plated tungsten rods are used for thin films of chromium in the electronics and optics industries. The advantage of using chrome rods over chrome chips are better thermal efficiency, regulation of film thickness and elimination of spitting and spalling which can cause pinhole type defects.

Technical Downloads

The RD Mathis Company offer several technical papers that relate to various aspects of the thin film coating process and the Thermal Evaporation Method of depositing materials in vacuum. Discover the papers to gain an insight specific thin film coating questions.