Forging Perfection: Testbourne’s Metal Refining Service

In the heart of innovation lies Testbourne – a trailblazer in the realm of metal refining. As industries evolve and demand for high-quality materials soar, Testbourne stands at the forefront, wavering science and craftsmanship into a seamless tapestry of precision.

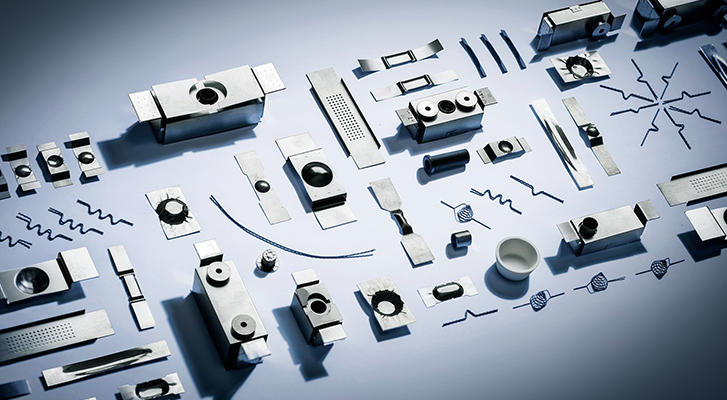

At Testbourne, we offer a comprehensive reclaim service for precious metals and other materials. From old sputtering targets to evaporation materials, we can refine many different material forms.

The Metal Refining Process

Metal refining is a meticulous process designed to enhance the purity and properties of metals, ensuring they meet the stringent requirements of various industries. This transformative process involves the removal of impurities and the fine-tuning of alloy compositions, resulting in materials that exhibit exceptional strength, conductivity and corrosion resistance.

Testbourne’s Metal Refining Process

Testbourne differs by providing cutting-edge metal refining solutions that cater to the unique needs of diverse industries. Leveraging state-of-the-art technology and a team of skilled experts, Testbourne offers a comprehensive suite of services.

Key Steps in the Metal Refining Process:

1. Material Analysis

The metal refining process starts with a meticulous analysis of the raw materials. We understand that every material is unique, and that is why we employ advanced techniques to identify impurities and understand the composition of the metal.

2. Alloy Development

For industries requiring specific alloy compositions, Testbourne excels in custom alloy development. This step involves the precise blending of elements to achieve desired properties, such as increased strength, conductivity, or resistance to environmental factors.

3. Purification Techniques

Testbourne employs a variety of purification techniques, including vacuum melting, zone refining, and electrolysis, to remove impurities from the metal. These methods ensure the final product meets or exceeds industry standards.

4. Quality Control

Rigorous quality control measures and protocols are implemented throughout the refining process. Testbourne utilises advanced testing equipment to verify the integrity of the refined metal, guaranteeing that it meets the highest quality benchmarks.

Materials Refined by Testbourne

Testbourne’s metal refining expertise extends to a wide range of materials, catering to the diverse needs of industries such as aerospace, electronics, healthcare and optics. Some of the materials that can undergo this process include:

Precious Metals:

Gold: Revered for its luxury qualities and unparalleled conductivity, the gold undergoes Testbourne’s refining process to ensure it meets the exacting standards demanded by industries ranging from electronics to jewellery.

Silver: Beyond its traditional role in coinage and adornments, silver’s conductivity makes it a crucial player in modern electronics. Testbourne can refine silver to enhance its purity, unlocking its full potential in technological applications.

Platinum: With its resistance to corrosion and high-temperature stability, platinum is a sought-after material in catalytic converters, fuel cells, and medical equipment. Metal refining elevates its properties, amplifying its efficacy across diverse sectors.

Ruthenium & Rhodium: These lesser-known precious metals find their niche in electronics, catalysts, and alloy enhancement. Testbourne’s refining expertise extracts their full potential, contributing to advancements in various industries.

Other Standard Materials:

Chromium: Known for its corrosion resistance and application in stainless steel, chromium undergoes Testbourne’s refining process to enhance its purity, ensuring its optimal performance in demanding environments.

Hafnium: Often used in the aerospace industry for its high melting point and neutron-absorbing properties, hafnium’s refinement guarantees its sustainability for critical applications.

Indium: A key player in the production of indium-tin-oxide used in touchscreens and solar panels, indium exhibits the purity required for cutting-edge technology.

Titanium: Renowned for its strength-to-weight ratio, titanium finds applications in aerospace, medical implants and sporting equipment. Testbourne’s refining process elevates titanium’s properties, ensuring its adaptability.

Tungsten: Essential in industrial tooling and electronics, tungsten undergoes precision refining to enhance its hardness and durability, making it a stalwart material in demanding applications.

Tantalum: With its corrosion resistance and high melting point, tantalum is refined to meet the stringent demands of electronic capacitors and medical devices.

Nickel, Molybdenum, Vanadium and Zirconium: These versatile metals, along with their alloys, benefit from the refining process to ensure they meet or exceed industry standards for strength, durability and purity.

Metal Refining with Testbourne

In the realm of metal refining, Testbourne emerges as a beacon of excellence. Our commitment to innovation, coupled with a passion for precision, enables industries to access materials of unparalleled quality. As technology continues to advance, Testbourne remains dedicated to pushing the boundaries of what is possible in the world of metal refinement, shaping the future of industries that rely on the strength and purity of their materials.

If you have any questions about our metal refining service or any of the products we offer, please get in touch with our team and we would be happy to help.